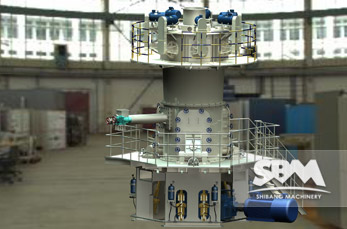

LUM Vertical Roller Mill

LUM vertical roller mill can be widely used in cement, power, metallurgy, chemical, non-metallic mineral industries. It combines crushing, drying, grinding, grading conveyor in one, high production efficiency, can be massive, granular and powdered materials ground into powder material required.

LUM Vertical Roller Mill Price And Cost Analysis

Vertical roller mill price level in the average price level of the market. Customers in the choice of grinding equipment, to consider the various factors, including physical properties, material production line design output per hour, the size of the production environment and investment cost etc.. Material handling process, in addition to use vertical roller mill equipment etc., need to use the broken equipment, transmission equipment, such as cone crusher, impact crusher, belt conveyors.

Vertical Roller Mill Has The Following Advantages In Processing

The first is the device itself does not need additional separator, separator and lifting equipment. The wear dust gas can be directly dust collector or electric dust collected by the bag, reduce the pollution of dust to the environment.

The second is the vertical roller mill production system has the advantages of simple process, compact layout, building area is small. The equipment covers an area of approximately 70% ball mill system, building space is about milling system 60% and open layout, directly reduce the investment of enterprise.

Finally is the vertical roller mill drying material ability. vertical roller mill hot-air conveying material, can control the inlet temperature of water in the material grinding larger, so that products meet the requirements of the final moisture. In the vertical roller mill grinding in water can be as high as 15%~20% drying, grinding into the material.

Technical Data

| Model | LUM1125 | LUM1232 | LUM1436 |

|---|---|---|---|

| Wheel diameter(mm) | 1100 | 1200 | 1400 |

| Capacity (t/h) | 5~12 | 7~16 | 8~18 |

| Fineness 400~650Mesh | ~D97 | ~D97 | ~D97 |

| Material Size(mm) | <10 | < 10 | <10 |

| Moisture | <3% | <3% | <3% |

| Main Motor Power(KW) | 250 | 315 | 355 |

| Roller(set) | 3 | 3 | 3 |

| Classifier Motor Power | 15 KWx5 | 15 KWx7 | 15 KWx7 |

Related Products

Ball Mill |

Raymond Mill |

LM Vertical Grinding Mills |