Ball Mill

Ball mill is the material to be broken, and then smash the key equipment, widely used in cement, silicate products, new building materials, refractory materials, fertilizer, ferrous and nonferrous metal and glass ceramics and other production industries of all kinds of ores and other grind-able materials can be dry or wet grinding.

Ball Mill Price And Cost Analysis

Based on continuous innovation and improvement of production technology, our company production of ball mill in saving energy and reducing consumption aspect, increase yield, green environmental protection has a good effect. The ball mill components of advanced structure, namely the wear resistance and impact resistance, reduce the production of energy consumption, but also can quickly and efficiently complete material grinding.

New type of lining plate of long service life, wide applicability, can meet different working condition requirements, greatly reducing the wear and the replacement cost of plate lining. At the same time, according to the degree of crushing material grading crusher can mill, large processing quantity, than the same size high device yields about 30%. And the ball mill of high degree of automation, reducing the work intensity of the workers, effectively reduces the production cost.

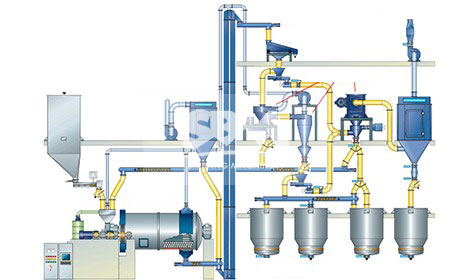

Ball Mill Production Line Equipment

In a complete ball mill production line, in addition to grinding equipment, also need other auxiliary equipment, such as the primary crushing equipment, second crushing equipment, feeder and other equipment.

Technical Data

| Model | Rotate Speed (r/min) | Grinding Media Weight (T) | Max.Feeding Size(mm) | Discharge Size (mm) | Output(t/h) | Motor Power (KW) |

|---|---|---|---|---|---|---|

| Ф900×1800 | 36~38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 |

| Ф900×3000 | 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 |

| Ф1200×2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 |

| Ф1200×3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 |

| Ф1200×4500 | 32.4 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 |

| Ф1500×3000 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 |

| Ф1500×4500 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 110 |

| Ф1500×5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 |

| Ф1830×3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 |

| Ф1830×4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 |

| Ф1830×6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 |

| Ф1830×7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 |

| Ф2100×3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5-36 | 155 |

| Ф2100×4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 |

| Ф2100×7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 8-48 | 280 |

| Ф2200×4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 |

| Ф2200×6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 |

| Ф2200×7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 |

| Ф2200×7500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 |

| Ф2400×3000 | 21 | 23 | ≤25 | 0.074-0.4 | 7-50 | 245 |

| Ф2400×4500 | 21 | 30 | ≤25 | 0.074-0.4 | 8.5-60 | 320 |

| Ф2700×4000 | 20.7 | 40 | ≤25 | 0.074-0.4 | 12-80 | 400 |

| Ф2700×4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 12-90 | 430 |

| Ф3200×4500 | 18 | 65 | ≤25 | 0.074-0.4 | According to the process condition | 800 |

Table 1: Technical Parameters of Wet Type and Rolling Bearing supporting the Ball Mill

| Model | Shell Size(mm) | Effective Volume(m3) | Grinding Media Weight(t) | Rotate Speed(r/min) | Power(Kw) | Discharge Size(㎜) | Output(t/h) | Remark |

|---|---|---|---|---|---|---|---|---|

| Dia×Length | ||||||||

| GMQG1530 | 1500×3000 | 4 | 8 | 27.6 | 75 | 0.8-0.074 | 12-2.8 | 380V |

| GMQG1535 | 1500×3500 | 4.6 | 11 | 27.6 | 75-90 | 0.8-0.074 | 14-3.4 | 380V |

| GMQG1830 | 1800×3000 | 6.5 | 13 | 25.3 | 132 | 0.8-0.074 | 21-4.8 | 380V |

| GMQG1835 | 1800×3500 | 7.58 | 16 | 25.3 | 160 | 0.8-0.074 | 25-5.8 | 380V |

| GMQG1840 | 1800×4000 | 8.65 | 17.3 | 25.3 | 185 | 0.8-0.074 | 28-6.6 | 380V |

| GMQG1845 | 1800×4500 | 9.75 | 19.5 | 25.3 | 210 | 0.8-0.074 | 31-7.2 | 380V |

| GMQG2122 | 2100×2200 | 6.7 | 14.7 | 23.8 | 160 | 0.8-0.074 | 24-5.3 | 380V |

| GMQG2130 | 2100×3000 | 9.2 | 17 | 23.8 | 185 | 0.8-0.074 | 26-6.0 | 380V |

| GMQG2136 | 2100×3600 | 11 | 19 | 23.8 | 210 | 0.8-0.074 | 29-6.5 | 380V |

| GMQG2140 | 2100×4000 | 12.2 | 20.5 | 23.8 | 220 | 0.8-0.074 | 32-7.2 | 380V |

| GMQG2145 | 2100×4500 | 13.8 | 22 | 23.8 | 250 | 0.8-0.074 | 36-8.1 | 380V |

| GMQG2424 | 2400×2400 | 9.8 | 20 | 22.8 | 220 | 0.8-0.074 | 32-6.6 | 380V |

| GMQG2430 | 2400×3000 | 12.2 | 25 | 22.8 | 250 | 0.8-0.074 | 38-7.5 | 380V |

| GMQG2436 | 2400×3600 | 14.6 | 30 | 22.8 | 280 | 0.8-0.074 | 42-8.5 | 380V |

| GMQG2440 | 2400×4000 | 16.2 | 33 | 22.8 | 355 | 0.8-0.074 | 47-9.5 | 380V |

| GMQG2445 | 2400×4500 | 18.2 | 37 | 22.8 | 400 | 0.8-0.074 | 55-10.5 | 380V |

| GMQG2721 | 2700×2100 | 10.7 | 24 | 21.7 | 280 | 3.0-0.074 | 84-8.5 | 6-10KV |

| GMQG2727 | 2700×2700 | 13.8 | 29 | 21.7 | 315 | 3.0-0.074 | 105-9.0 | 6-10KV |

| GMQG2730 | 2700×3000 | 15.3 | 32.5 | 21.7 | 355 | 3.0-0.074 | 120-10 | 6-10KV |

| GMQG2736 | 2700×3600 | 18.4 | 39 | 21.7 | 400 | 3.0-0.074 | 145-12 | 6-10KV |

| GMQG2740 | 2700×4000 | 20.5 | 43 | 21.7 | 450 | 3.0-0.074 | 159-13 | 6-10KV |

| GMQG2745 | 2700×4500 | 23 | 50 | 21.7 | 500 | 3.0-0.074 | 180-15 | 6-10KV |

| GMQG3231 | 3200×3100 | 22.65 | 46.9 | 18.6 | 500 | 3.0-0.074 | 182-16 | 6-10KV |

| GMQG3236 | 3200×3600 | 26.2 | 52 | 18.6 | 560 | 3.0-0.074 | 190-19 | 6-10KV |

| GMQG3240 | 3200×4000 | 29.2 | 57 | 18.6 | 630 | 3.0-0.074 | 210-22 | 6-10KV |

| GMQG3245 | 3200×4500 | 32.8 | 65 | 18.6 | 710-800 | 3.0-0.074 | 235-29 | 6-10KV |

| GMQG3254 | 3200×5400 | 39.2 | 81.6 | 18.6 | 800-1000 | 3.0-0.074 | 280-35 | 6-10KV |

| GMQG3640 | 3600×4000 | 35.6 | 75 | 17.3 | 800 | 3.0-0.074 | 230-25 | 6-10KV |

| GMQG3645 | 3600×4500 | 40.8 | 88 | 17.3 | 1000 | 3.0-0.074 | 259-29 | 6-10KV |

| GMQG3650 | 3600×5000 | 45.3 | 96 | 17.3 | 1120 | 3.0-0.074 | 288-35 | 6-10KV |

| GMQG3660 | 3600×6000 | 54.4 | 117 | 17.3 | 1250-1500 | 3.0-0.074 | 310-38 | 6-10KV |

| GMQG3685 | 3600×8500 | 79 | 144 | 17.3 | 1800 | 3.0-0.074 | 450-50 | 6-10KV |

Table 2: Technical Parameters of Dry Type Over-Flow and Rolling Bearing supporting the Ball Mill

| Model | Shell Size(mm) | Effective Volume(m3) | Grinding Media Weight(t) | Rotate Speed(r/min) | Power(Kw) | Discharge Size(㎜) | Output(t/h) | Remark |

|---|---|---|---|---|---|---|---|---|

| Dia×Length | ||||||||

| GMQY1530 | 1500×3000 | 4 | 8.4 | 27.6 | 75 | 0.8-0.074 | 11-2.6 | 380V |

| GMQY1535 | 1500×3500 | 4.6 | 10 | 27.6 | 75-90 | 0.8-0.074 | 13.2-3.0 | 380V |

| GMQY1830 | 1800×3000 | 6.5 | 12 | 25.3 | 110-132 | 0.8-0.074 | 20-4.5 | 380V |

| GMQY1835 | 1800×3500 | 7.58 | 15 | 25.3 | 132-160 | 0.8-0.074 | 23-5.0 | 380V |

| GMQY1840 | 1800×4000 | 8.65 | 16 | 25.3 | 160-185 | 0.8-0.074 | 25-6.0 | 380V |

| GMQY1845 | 1800×4500 | 9.75 | 18 | 25.3 | 185-210 | 0.8-0.074 | 28-6.8 | 380V |

| GMQY2122 | 2100×2200 | 6.7 | 14.7 | 23.8 | 160 | 0.8-0.074 | 22-5.0 | 380V |

| GMQY2130 | 2100×3000 | 9.2 | 17 | 23.8 | 185 | 0.8-0.074 | 25-5.8 | 380V |

| GMQY2136 | 2100×3600 | 11 | 19 | 23.8 | 210 | 0.8-0.074 | 28-6.0 | 380V |

| GMQY2140 | 2100×4000 | 12.2 | 20.5 | 23.8 | 220 | 0.8-0.074 | 30-7.0 | 380V |

| GMQY2145 | 2100×4500 | 13.8 | 22 | 23.8 | 250 | 0.8-0.074 | 34-8.0 | 380V |

| GMQY2424 | 2400×2400 | 9.8 | 18.8 | 22.8 | 210 | 0.8-0.074 | 30-6.2 | 380V |

| GMQY2430 | 2400×3000 | 12.2 | 23 | 22.8 | 250 | 0.8-0.074 | 34-6.6 | 380V |

| GMQY2436 | 2400×3600 | 14.6 | 25 | 22.8 | 280 | 0.8-0.074 | 40.5-7.9 | 380V |

| GMQY2440 | 2400×4000 | 16.2 | 28 | 22.8 | 315 | 0.8-0.074 | 45-8.7 | 380V |

| GMQY2445 | 2400×4500 | 18.2 | 31 | 22.8 | 355 | 0.8-0.074 | 50-9.8 | 380V |

| GMQY2721 | 2700×2100 | 10.7 | 20 | 21.7 | 280 | 3.0-0.074 | 76-6.0 | 6-10KV |

| GMQY2727 | 2700×2700 | 13.8 | 25.5 | 21.7 | 315 | 3.0-0.074 | 98-7.8 | 6-10KV |

| GMQY2730 | 2700×3000 | 15.3 | 28 | 21.7 | 355 | 3.0-0.074 | 108-8.8 | 6-10KV |

| GMQY2736 | 2700×3600 | 18.4 | 34 | 21.7 | 355-400 | 3.0-0.074 | 130-10.5 | 6-10KV |

| GMQY2740 | 2700×4000 | 20.5 | 37 | 21.7 | 400-450 | 3.0-0.074 | 144-11.5 | 6-10KV |

| GMQY2745 | 2700×4500 | 23 | 42.5 | 21.7 | 500 | 3.0-0.074 | 180-13 | 6-10KV |

| GMQY3231 | 3200×3100 | 22.65 | 22.65 | 18.6 | 450 | 3.0-0.074 | 164-14.4 | 6-10KV |

| GMQY3236 | 3200×3600 | 26.2 | 26.2 | 18.6 | 500 | 3.0-0.074 | 171-17.1 | 6-10KV |

| GMQY3240 | 3200×4000 | 29.2 | 29.2 | 18.6 | 560 | 3.0-0.074 | 190-20 | 6-10KV |

| GMQY3245 | 3200×4500 | 32.8 | 61 | 18.6 | 630 | 3.0-0.074 | 228-22 | 6-10KV |

| GMQY3254 | 3200×5400 | 39.3 | 73 | 18.6 | 710 | 3.0-0.074 | 270-26 | 6-10KV |

| GMQY3640 | 3600×4000 | 35.6 | 67 | 17.3 | 710 | 3.0-0.074 | 210-20 | 6-10KV |

| GMQY3645 | 3600×4500 | 40.8 | 76 | 17.3 | 800-1000 | 3.0-0.074 | 233-26 | 6-10KV |

| GMQY3650 | 3600×5000 | 45.3 | 86 | 17.3 | 1120 | 3.0-0.074 | 260-31.5 | 6-10KV |

| GMQY3660 | 3600×6000 | 54.4 | 102 | 17.3 | 1250 | 3.0-0.074 | 280-34 | 6-10KV |

| GMQY3685 | 3600×8500 | 79 | 131 | 17.3 | 1500 | 3.0-0.074 | 400-45 | 6-10KV |

Related Products

LM Vertical Grinding Mills |

Raymond Mill |

LUM Vertical Roller Mill |