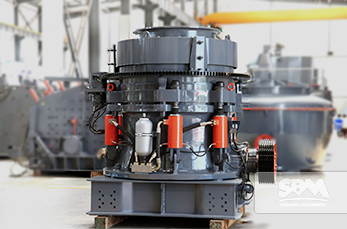

HPT Cone Crusher

HPT Cone Crusher Detail

HPT cone crusher, short for multi-cylinder hydraulic cone crusher is the introduction of the latest German technology and the development of high-energy cone crusher has the world's advanced level. By using a special intergranular laminating crushing chamber design principles and matching speed, replacing the traditional single particle crushing principle, achieve selective crushing of materials, broken uniform size. Rail-way through the release of hydraulic cylinders allow the iron smoothly through the crushing chamber, and in the event of excessive iron and transient nausea vehicle under circumstances, to hydraulic lifting roof, automatic nesting, avoiding the spring cone crusher downtime maintenance operations. Crushing cavity using high-performance non-contact labyrinth seals, improves the reliability of the dust barrier, reducing the wear cycle iron contamination and equipment, plus the body carries unique lubrication system, greatly improving the service life of HPT cone crusher.

HPT Cone Crusher Structure Optimization

- Increase the eccentricity, improves the production capacity.

- Accelerate the breaking frequency, increase the power, improve the crushing fineness.

- Increase the moving cone swing center, optimization of the cavity shape design of HPT cone crusher.

- Liner plate thickening, prolongation of life.

- The hydraulic motor to replace the hydraulic push rod device, row ore mouth can be precisely adjusted continuously, and cone assembly is set at 10 minutes down.

- The hydraulic cylinder cone crusher to replace the spring cone crusher, iron travel increase, improve the reliability of.

- Separate, spindle and spindle moving cone, changed to fixed stubby cylinder, large bearing capacity, dynamic cone without limit autobiography speed, improve the HPT cone crusher speed.

- Two-way hydraulic cylinder, a few minutes to clean the crushing cavity.

- The abolition of water seal ring, changed to the patent technology of non contact TU seal.

Technical Data

| Model | Cavity | Maximum Feeding Size(mm) | Minimum Discharging Size(mm) | Capacity(t/h) | Maximum Installed Power(kw) |

|---|---|---|---|---|---|

| HPT100 | C1(Extra Coarse) | 140 | 19 | 50-140 | 90 |

| C2(Coarse) | 100 | 13 | |||

| M(Medium) | 70 | 9 | |||

| F1(Fine) | 50 | 9 | |||

| F2(Extra Fine) | 20 | 6 | |||

| HPT200 | C2(Coarse) | 185 | 19 | 90-250 | 160 |

| M(Medium) | 125 | 16 | |||

| F1(Fine) | 95 | 13 | |||

| F2(Extra Fine) | 75 | 10 | |||

| HPT300 | C1(Extra Coarse) | 230 | 25 | 110-440 | 250 |

| C2(Coarse) | 210 | 19 | |||

| M(Medium) | 150 | 16 | |||

| F1(Fine) | 105 | 13 | |||

| F2(Extra Fine) | 80 | 10 | |||

| HPT400 | C1(Extra Coarse) | 295 | 30 | 135-630 | 315 |

| C2(Coarse) | 251 | 25 | |||

| M(Medium) | 196 | 20 | |||

| F1(Fine) | 110 | 13 | |||

| F2(Extra Fine) | 90 | 10 | |||

| HPT500 | C1(Extra Coarse) | 330 | 38 | 220-790 | 400 |

| C2(Coarse) | 290 | 30 | |||

| M(Medium) | 210 | 22 | |||

| F1(Fine) | 135 | 16 | |||

| F2(Extra Fine) | 95 | 13 | |||

| HPT800 | C1(Extra Coarse) | 350 | 38 | 310-1200 | 630 |

| C2(Coarse) | 299 | 32 | |||

| M(Medium) | 265 | 25 | |||

| F1(Fine) | 220 | 16 | |||

| F2(Extra Fine) | 150 | 13 |

Related Products

CS Cone Crusher |

HST Cone Crusher |

PY Cone Crusher |