LM Vertical Grinding Mills

LM vertical grinding mills is widely absorb the advanced technology in the foundation of international well-known company, combined with our thirty years of grinding equipment production experience, integrated design and development of a set of crushing, grinding, powder selection, drying, material handling and other functions in one of the five major large grinding equipment, has the process is concentrated, covers an area of small, less investment, high efficiency, energy saving, environmental protection and many other features.

LM Vertical Grinding Mills Application

LM vertical grinding mills can be divied into the mine mill, coal mill, hard mill three types.

- Mine mill is applicable to the cement industry raw material industry;

- Coal mill can be widely applied to pulverized coal, power, iron and steel, cement, building materials, metallurgy chemical industry preparation;

- Hard mill for steel, iron slag, slag, also suitable for cement clinker and other chemical raw material etc..

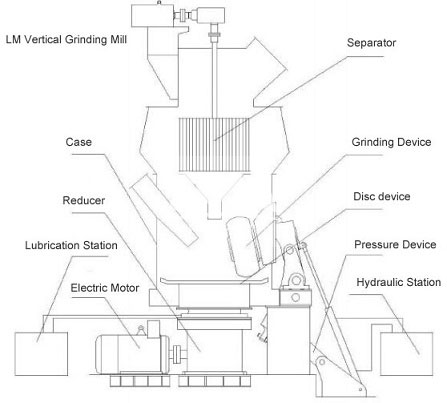

LM Vertical Grinding Mills Working Principle

The main motor drives the disc through the speed reducer to rotate, and the hot air from the air inlet into the vertical grinding mill body, material from the feeding port to the central disc and under the action of centrifugal force from the disc center to the edge of uniform movement, after roller grinding area disc, by grinding roller compaction, bulk material directly crushed, fine materials by after extrusion forming material bed of interparticle breakage. Crushed material continues to move to the edge of the grinding disc, a strong current of air until it is wind at ring away, and granular materials with large again fell to the disc to smash, airflow in the upper part of the separator material through, in the rotor blade under the effect of coarse particles, back to the disc grinding, fine powder qualified with air together by grinding, powder collector collection system and discharge is finished powder. Mixed material of impurities such as iron as material moves to the edge of the grinding disc, due to its own weight dropped to mill subarachnoid, and is mounted on the disc at the bottom of the scraping plate scraping slag outlet discharge machine.

Technical Data

| Model | Rotate Speed (r/min) | Grinding Media Weight (T) | Max.Feeding Size(mm) | Discharge Size (mm) | Output(t/h) | Motor Power (KW) |

|---|---|---|---|---|---|---|

| Ф900×1800 | 36~38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 |

| Ф900×3000 | 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 |

| Ф1200×2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 |

| Ф1200×3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 |

| Ф1200×4500 | 32.4 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 |

| Ф1500×3000 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 |

| Ф1500×4500 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 110 |

| Ф1500×5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 |

| Ф1830×3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 |

| Ф1830×4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 |

| Ф1830×6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 |

| Ф1830×7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 |

| Ф2100×3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5-36 | 155 |

| Ф2100×4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 |

| Ф2100×7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 8-48 | 280 |

| Ф2200×4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 |

| Ф2200×6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 |

| Ф2200×7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 |

| Ф2200×7500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 |

| Ф2400×3000 | 21 | 23 | ≤25 | 0.074-0.4 | 7-50 | 245 |

| Ф2400×4500 | 21 | 30 | ≤25 | 0.074-0.4 | 8.5-60 | 320 |

| Ф2700×4000 | 20.7 | 40 | ≤25 | 0.074-0.4 | 12-80 | 400 |

| Ф2700×4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 12-90 | 430 |

| Ф3200×4500 | 18 | 65 | ≤25 | 0.074-0.4 | According to the process condition | 800 |

Table 1: Technical Parameters of Wet Type and Rolling Bearing supporting the LM Vertical Grinding Mills

| Model | Shell Size(mm) | Effective Volume(m3) | Grinding Media Weight(t) | Rotate Speed(r/min) | Power(Kw) | Discharge Size(㎜) | Output(t/h) | Remark |

|---|---|---|---|---|---|---|---|---|

| Dia×Length | ||||||||

| GMQG1530 | 1500×3000 | 4 | 8 | 27.6 | 75 | 0.8-0.074 | 12-2.8 | 380V |

| GMQG1535 | 1500×3500 | 4.6 | 11 | 27.6 | 75-90 | 0.8-0.074 | 14-3.4 | 380V |

| GMQG1830 | 1800×3000 | 6.5 | 13 | 25.3 | 132 | 0.8-0.074 | 21-4.8 | 380V |

| GMQG1835 | 1800×3500 | 7.58 | 16 | 25.3 | 160 | 0.8-0.074 | 25-5.8 | 380V |

| GMQG1840 | 1800×4000 | 8.65 | 17.3 | 25.3 | 185 | 0.8-0.074 | 28-6.6 | 380V |

| GMQG1845 | 1800×4500 | 9.75 | 19.5 | 25.3 | 210 | 0.8-0.074 | 31-7.2 | 380V |

| GMQG2122 | 2100×2200 | 6.7 | 14.7 | 23.8 | 160 | 0.8-0.074 | 24-5.3 | 380V |

| GMQG2130 | 2100×3000 | 9.2 | 17 | 23.8 | 185 | 0.8-0.074 | 26-6.0 | 380V |

| GMQG2136 | 2100×3600 | 11 | 19 | 23.8 | 210 | 0.8-0.074 | 29-6.5 | 380V |

| GMQG2140 | 2100×4000 | 12.2 | 20.5 | 23.8 | 220 | 0.8-0.074 | 32-7.2 | 380V |

| GMQG2145 | 2100×4500 | 13.8 | 22 | 23.8 | 250 | 0.8-0.074 | 36-8.1 | 380V |

| GMQG2424 | 2400×2400 | 9.8 | 20 | 22.8 | 220 | 0.8-0.074 | 32-6.6 | 380V |

| GMQG2430 | 2400×3000 | 12.2 | 25 | 22.8 | 250 | 0.8-0.074 | 38-7.5 | 380V |

| GMQG2436 | 2400×3600 | 14.6 | 30 | 22.8 | 280 | 0.8-0.074 | 42-8.5 | 380V |

| GMQG2440 | 2400×4000 | 16.2 | 33 | 22.8 | 355 | 0.8-0.074 | 47-9.5 | 380V |

| GMQG2445 | 2400×4500 | 18.2 | 37 | 22.8 | 400 | 0.8-0.074 | 55-10.5 | 380V |

| GMQG2721 | 2700×2100 | 10.7 | 24 | 21.7 | 280 | 3.0-0.074 | 84-8.5 | 6-10KV |

| GMQG2727 | 2700×2700 | 13.8 | 29 | 21.7 | 315 | 3.0-0.074 | 105-9.0 | 6-10KV |

| GMQG2730 | 2700×3000 | 15.3 | 32.5 | 21.7 | 355 | 3.0-0.074 | 120-10 | 6-10KV |

| GMQG2736 | 2700×3600 | 18.4 | 39 | 21.7 | 400 | 3.0-0.074 | 145-12 | 6-10KV |

| GMQG2740 | 2700×4000 | 20.5 | 43 | 21.7 | 450 | 3.0-0.074 | 159-13 | 6-10KV |

| GMQG2745 | 2700×4500 | 23 | 50 | 21.7 | 500 | 3.0-0.074 | 180-15 | 6-10KV |

| GMQG3231 | 3200×3100 | 22.65 | 46.9 | 18.6 | 500 | 3.0-0.074 | 182-16 | 6-10KV |

| GMQG3236 | 3200×3600 | 26.2 | 52 | 18.6 | 560 | 3.0-0.074 | 190-19 | 6-10KV |

| GMQG3240 | 3200×4000 | 29.2 | 57 | 18.6 | 630 | 3.0-0.074 | 210-22 | 6-10KV |

| GMQG3245 | 3200×4500 | 32.8 | 65 | 18.6 | 710-800 | 3.0-0.074 | 235-29 | 6-10KV |

| GMQG3254 | 3200×5400 | 39.2 | 81.6 | 18.6 | 800-1000 | 3.0-0.074 | 280-35 | 6-10KV |

| GMQG3640 | 3600×4000 | 35.6 | 75 | 17.3 | 800 | 3.0-0.074 | 230-25 | 6-10KV |

| GMQG3645 | 3600×4500 | 40.8 | 88 | 17.3 | 1000 | 3.0-0.074 | 259-29 | 6-10KV |

| GMQG3650 | 3600×5000 | 45.3 | 96 | 17.3 | 1120 | 3.0-0.074 | 288-35 | 6-10KV |

| GMQG3660 | 3600×6000 | 54.4 | 117 | 17.3 | 1250-1500 | 3.0-0.074 | 310-38 | 6-10KV |

| GMQG3685 | 3600×8500 | 79 | 144 | 17.3 | 1800 | 3.0-0.074 | 450-50 | 6-10KV |

Table 2: Technical Parameters of Dry Type Over-Flow and Rolling Bearing supporting the LM Vertical Grinding Mills

| Model | Shell Size(mm) | Effective Volume(m3) | Grinding Media Weight(t) | Rotate Speed(r/min) | Power(Kw) | Discharge Size(㎜) | Output(t/h) | Remark |

|---|---|---|---|---|---|---|---|---|

| Dia×Length | ||||||||

| GMQY1530 | 1500×3000 | 4 | 8.4 | 27.6 | 75 | 0.8-0.074 | 11-2.6 | 380V |

| GMQY1535 | 1500×3500 | 4.6 | 10 | 27.6 | 75-90 | 0.8-0.074 | 13.2-3.0 | 380V |

| GMQY1830 | 1800×3000 | 6.5 | 12 | 25.3 | 110-132 | 0.8-0.074 | 20-4.5 | 380V |

| GMQY1835 | 1800×3500 | 7.58 | 15 | 25.3 | 132-160 | 0.8-0.074 | 23-5.0 | 380V |

| GMQY1840 | 1800×4000 | 8.65 | 16 | 25.3 | 160-185 | 0.8-0.074 | 25-6.0 | 380V |

| GMQY1845 | 1800×4500 | 9.75 | 18 | 25.3 | 185-210 | 0.8-0.074 | 28-6.8 | 380V |

| GMQY2122 | 2100×2200 | 6.7 | 14.7 | 23.8 | 160 | 0.8-0.074 | 22-5.0 | 380V |

| GMQY2130 | 2100×3000 | 9.2 | 17 | 23.8 | 185 | 0.8-0.074 | 25-5.8 | 380V |

| GMQY2136 | 2100×3600 | 11 | 19 | 23.8 | 210 | 0.8-0.074 | 28-6.0 | 380V |

| GMQY2140 | 2100×4000 | 12.2 | 20.5 | 23.8 | 220 | 0.8-0.074 | 30-7.0 | 380V |

| GMQY2145 | 2100×4500 | 13.8 | 22 | 23.8 | 250 | 0.8-0.074 | 34-8.0 | 380V |

| GMQY2424 | 2400×2400 | 9.8 | 18.8 | 22.8 | 210 | 0.8-0.074 | 30-6.2 | 380V |

| GMQY2430 | 2400×3000 | 12.2 | 23 | 22.8 | 250 | 0.8-0.074 | 34-6.6 | 380V |

| GMQY2436 | 2400×3600 | 14.6 | 25 | 22.8 | 280 | 0.8-0.074 | 40.5-7.9 | 380V |

| GMQY2440 | 2400×4000 | 16.2 | 28 | 22.8 | 315 | 0.8-0.074 | 45-8.7 | 380V |

| GMQY2445 | 2400×4500 | 18.2 | 31 | 22.8 | 355 | 0.8-0.074 | 50-9.8 | 380V |

| GMQY2721 | 2700×2100 | 10.7 | 20 | 21.7 | 280 | 3.0-0.074 | 76-6.0 | 6-10KV |

| GMQY2727 | 2700×2700 | 13.8 | 25.5 | 21.7 | 315 | 3.0-0.074 | 98-7.8 | 6-10KV |

| GMQY2730 | 2700×3000 | 15.3 | 28 | 21.7 | 355 | 3.0-0.074 | 108-8.8 | 6-10KV |

| GMQY2736 | 2700×3600 | 18.4 | 34 | 21.7 | 355-400 | 3.0-0.074 | 130-10.5 | 6-10KV |

| GMQY2740 | 2700×4000 | 20.5 | 37 | 21.7 | 400-450 | 3.0-0.074 | 144-11.5 | 6-10KV |

| GMQY2745 | 2700×4500 | 23 | 42.5 | 21.7 | 500 | 3.0-0.074 | 180-13 | 6-10KV |

| GMQY3231 | 3200×3100 | 22.65 | 22.65 | 18.6 | 450 | 3.0-0.074 | 164-14.4 | 6-10KV |

| GMQY3236 | 3200×3600 | 26.2 | 26.2 | 18.6 | 500 | 3.0-0.074 | 171-17.1 | 6-10KV |

| GMQY3240 | 3200×4000 | 29.2 | 29.2 | 18.6 | 560 | 3.0-0.074 | 190-20 | 6-10KV |

| GMQY3245 | 3200×4500 | 32.8 | 61 | 18.6 | 630 | 3.0-0.074 | 228-22 | 6-10KV |

| GMQY3254 | 3200×5400 | 39.3 | 73 | 18.6 | 710 | 3.0-0.074 | 270-26 | 6-10KV |

| GMQY3640 | 3600×4000 | 35.6 | 67 | 17.3 | 710 | 3.0-0.074 | 210-20 | 6-10KV |

| GMQY3645 | 3600×4500 | 40.8 | 76 | 17.3 | 800-1000 | 3.0-0.074 | 233-26 | 6-10KV |

| GMQY3650 | 3600×5000 | 45.3 | 86 | 17.3 | 1120 | 3.0-0.074 | 260-31.5 | 6-10KV |

| GMQY3660 | 3600×6000 | 54.4 | 102 | 17.3 | 1250 | 3.0-0.074 | 280-34 | 6-10KV |

| GMQY3685 | 3600×8500 | 79 | 131 | 17.3 | 1500 | 3.0-0.074 | 400-45 | 6-10KV |

Related Products

Ball Mill |

Raymond Mill |

LUM Vertical Roller Mill |