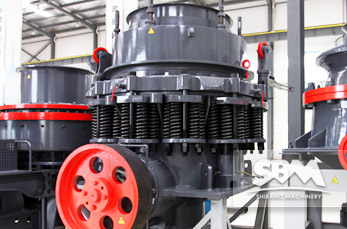

CS Cone Crusher

Detail About CS Cone Crusher

CS cone crusher is one of spring cone crusher, It is widely used in metallurgical industry, building materials industry, road building industry, chemical industry and silicate industry, suitable for crushing medium or above hardness ores and rocks.

Improve Performance Of CS Cone Crusher

On the reduced CS cone crusher weight, increasing volume of cone crusher, can reduce energy consumption, and improve work efficiency of cone crusher;

To improve the speed, can make the unit time broken materials become more accelerating, adding materials to the cone crusher, also can effectively improve the performance of CS cone crusher;

The experimental data show that: crushing elliptic ball medium was the highest, so before put into the cone crusher in the material can be the first treatment into an oval, so as to improve the work efficiency of cone crusher.

CS Cone Crusher Working Principle

When CS cone crusher work, the rotation of the motor through the pulley or coupling, drive shaft and eccentric conical part in forcing week moving around a fixed point for the next spin pendulum motion. So that the cone crusher broken wall sometimes and sometimes they leave the solid-mounted close to the adjustment sleeve rolling acetabular wall surface, the ore constantly under attack in the crushing cavity, pressing and bending and crushing ore achieved. Bevel gear drive motor through the eccentric rotation, so that the cone crusher for Swing movement. Sometimes close but sometimes broken cone away from the fixed cone, complete crushing and nesting. Support sleeve and the frame body connection by spring-loaded, when fall within the crusher and other non-metal block broken objects, which produce compression springs, exhaust foreign body, to achieve insurance, to prevent damage to the machine.

Technical Data

| Model | Movable Cone Diametermm (inch) | Chamber Style | Opening Side | Closed Side | Discharging Opening (mm) | REV (r/min) | Power (kw) | Motor Model | Capacity (t/h) | Machine Size (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| Max.Feeding (mm) | ||||||||||

| CSB75 | 900 (3′) | medium | 83 | 102 | 9-22 | 580 | 6-75 | Y315S-6/75 | 45-91 | 2821×1880 ×2164 |

| coarse | 159 | 175 | 13-38 | 59-163 | ||||||

| CSD75 | 914 (3′) | fine | 13 | 41 | 3-13 | 580 | 6-75 | Y315S-6/75 | 27-90 | 2821×1880 ×2410 |

| medium | 33 | 60 | 3-16 | 27-100 | ||||||

| coarse | 51 | 76 | 6-19 | 65-140 | ||||||

| CSB160 | 1295 (4 1/4′) | fine | 109 | 137 | 13-31 | 485 | 6-185 | Y355M2-6/185 | 109-181 | 2800×2342 ×2668 |

| medium | 188 | 210 | 16-31 | 132-253 | ||||||

| coarse | 216 | 241 | 19-51 | 172-349 | ||||||

| CSD160 | 1295 (4 1/4′) | fine | 29 | 64 | 3-16 | 485 | 6-160 | Y355M1-6/160 | 36-163 | 2800×2342 ×2668 |

| medium | 54 | 89 | 6-16 | 82-163 | ||||||

| coarse | 70 | 105 | 10-25 | 109-227 | ||||||

| CSB240 | 1650 (5 1/2′) | fine | 188 | 209 | 16-38 | 485 | 6-240 | 181-327 | 3911×2870 ×3771 | |

| medium | 213 | 241 | 22-51 | 258-417 | ||||||

| coarse | 241 | 268 | 25-64 | 299-635 | ||||||

| CSD240 | 1650 (5 1/2′) | fine | 35 | 70 | 5-13 | 485 | 6-240 | 90-209 | 3917×2870 ×3771 | |

| medium | 54 | 89 | 6-19 | 136-281 | ||||||

| coarse | 98 | 133 | 10-25 | 190-336 | ||||||

| CSB400 | 2134 (7′) | fine | 253 | 278 | 19-38 | 435 | 6-400 | 381-726 | 5200×4300 ×4700 | |

| medium | 303 | 334 | 25-51 | 608-998 | ||||||

| coarse | 334 | 369 | 31-64 | 870-1400 | ||||||

| CSD400 | 2134 (7′) | fine | 51 | 105 | 5-16 | 435 | 6-400 | 190-408 | 5200×4300 ×4700 | |

| medium | 95 | 133 | 10-19 | 354-508 | ||||||

| coarse | 127 | 178 | 13-25 | 454-599 | ||||||

Related Products

HPT Cone Crusher |

HST Cone Crusher |

PY Cone Crusher |