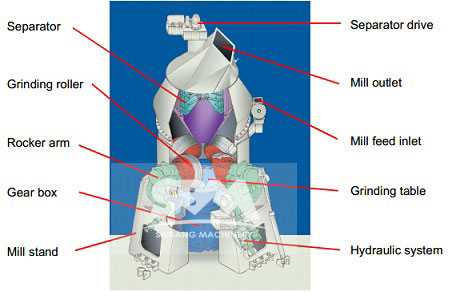

The vertical roller mill is mainly composed of separator, grinding roller, grinding table, hydraulic system, reducer, motor and other spare parts.

The separator is an important component for ensuring the product fineness, it consists of the drive system, rotor, guide vanes, a shell, a coarse powder blanking cone, outlet etc..

The grinding roller is the main components of compacted crushed on the material, which is composed of roller, roller, shaft, bearing and roll heart bracket etc.. Each friction has 2 ~ 4 grinding roller.

Grinding table is fixed on the vertical shaft speed reducer, speed reducer drives the grinding disc to rotate by. Different types of vertical mill grinding disc shape is different, the grinding disc by disc seat, liner material retaining ring, etc..

The hydraulic system is provided an important part of grinding pressure, which is composed of high pressure oil station, a hydraulic cylinder, a pull rod, an energy accumulator and the like, can exert enough pressure to make the material crushing and grinding roller. But the spring pressure device.

Reducer should reduce the speed and power transmission, drive disc rotation effect, but also bear the weight of the material grinding, and the grinding force.

Pre Article: How To Reduce Noise Of Vertical Roller Mill

Next Article: Vertical Roller Mill Routine Maintenance